In the high-stakes world of global manufacturing, few things can grind an industry to a halt like a chip shortage. We’ve been here before—remember 2021, when the semiconductor squeeze turned car factories into ghost towns and smartphone launches into pipe dreams? Fast forward to late 2025, and the ghosts are rattling chains again. This time, it’s not just pandemic fallout; it’s a toxic brew of AI-fueled demand, geopolitical saber-rattling, and underinvestment in the nuts-and-bolts of chip production. For China’s electronics supply chain — the beating heart of everything from EVs to consumer gadgets—this could spell trouble on a scale we haven’t seen in years.

As someone who’s covered the intersections of business, tech, and policy for years, I can tell you: this isn’t hyperbole. Bloomberg’s latest dispatches paint a picture of a supply chain teetering on the edge, with U.S. export controls tightening like a noose and Chinese firms scrambling to fill the void. Drawing from announcements and data released in the past three months, let’s break it down: why it’s happening now, who’s feeling the pain, and what it means for B2B sourcers navigating this minefield. Buckle up—because if history is any guide, ignoring these warning signs could cost billions.

Echoes of the Past, Shadows of the Future: Why the Chip Shortage Is Back

The original chip crunch of the early 2020s was a perfect storm: COVID demand spikes met supply chain snarls. By 2022, things eased, with global sales rebounding to record levels in 2024. But experts are now sounding alarms for a sequel, particularly in mature node semiconductors—those workhorse 40nm and larger chips powering everything from automotive sensors to industrial controls.

According to a mid-August analysis, underinvestment in these legacy nodes is the culprit. While billions pour into bleeding-edge 3nm tech for AI supercomputers, mature nodes have been neglected. By late 2024, automotive chip inventories are projected to hit rock-bottom levels, just as demand surges from Europe’s EV boom and rebounding consumer electronics. Fast-forward to Q3 2024 data, and the picture darkens: analog chips, reliant on these nodes, could bottleneck light-vehicle production as demand per car jumps 23% by 2026 compared to 2022 levels.

Enter China, the world’s electronics manufacturing powerhouse. As the largest consumer of semiconductors, Beijing’s push for self-sufficiency—aiming for 50% domestic production by year’s end—collides head-on with these constraints. Recent reports highlight how U.S. export curbs, tightened in September, are exacerbating the strain, targeting not just advanced chips but manufacturing equipment that China desperately needs. The result? A potential mismatch where global demand outpaces supply by 20% or more in key components, rippling through China’s factories.

Huawei’s Bold Bet: Doubling Down Amid Nvidia’s China Woes

No story captures this tension better than Huawei’s aggressive pivot. In a move straight out of a tech thriller, the Chinese giant is set to double production of its flagship Ascend 910C AI chip next year, targeting 600,000 units after hitting similar numbers in 2025. This ramp-up isn’t just ambition; it’s survival. With Nvidia faltering in China due to U.S. sanctions—sales there have plummeted—Huawei sees an opening to capture the domestic AI market, projected to explode as data centers gobble up GPUs.

But here’s the rub: scaling to 1.6 million dies by 2026 requires raw materials, tools, and fabs that are increasingly hard to come by. Bloomberg sources familiar with the matter note that 2025’s sanction-induced headaches have already delayed timelines, forcing Huawei to lean on domestic suppliers. For China’s broader electronics ecosystem, this means intensified competition for scarce high-bandwidth memory (HBM) and substrates—components where supply risks could spike 30% by 2026 due to AI demand alone.

Think about the downstream effects. Shenzhen’s assembly lines, churning out everything from smartphones to smart home devices, rely on these chips. A Huawei surge could sideline smaller players, driving up costs for B2B buyers sourcing electronic components. Early indicators from Q3 show lead times stretching 20-30% longer for AI-related parts, a harbinger of broader shortages.

Rumors, Rallies, and Reality: The Chip Machine Mirage

If Huawei’s moves are the calculated play, then the recent frenzy over “elusive chip machines” is pure market drama. Just days ago, whispers of breakthroughs in extreme ultraviolet (EUV) lithography tools—holy grails for advanced chipmaking—sparked a Nasdaq-like rally in Chinese tech stocks. Investors, betting on China’s AI edge, poured in, lifting chipmakers like SMIC by double digits in a single session.

Yet, as Bloomberg’s newsletter dissects, these rumors often fizzle. The real story? China’s capacity expansion in mature nodes positions it as a potential kingmaker in any shortage. With plans to add more wafer starts than the rest of the world combined this year, Beijing could wield supply as a geopolitical lever—perhaps easing tensions with the West or pressuring rivals. For electronics sourcers, this volatility means hedging bets: diversify now, or risk paying premiums when the crunch hits.

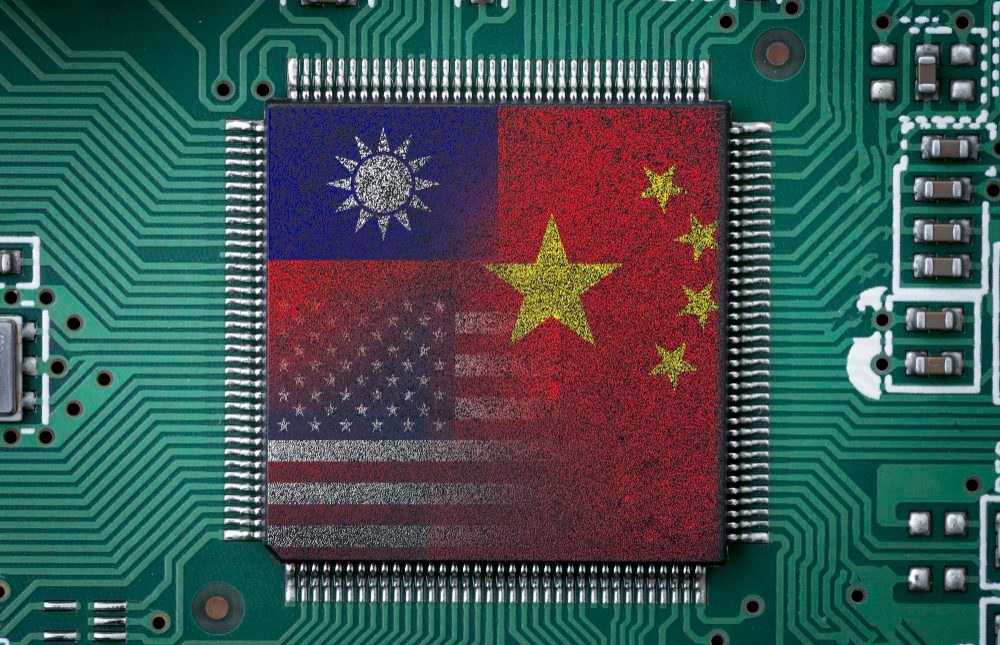

Geopolitical Fault Lines: Taiwan, Export Controls, and the Taiwan Strait Shadow

No chip shortage discussion is complete without the Taiwan factor. Taiwan’s semiconductor dominance—producing over 90% of the world’s advanced chips—serves as a deterrent against Chinese aggression, but recent U.S. pleas to relocate production stateside have met stiff resistance. TSMC’s expansions in Arizona are underway, but full shifts? Unlikely, given the island’s water and talent constraints.

Layer on September’s U.S. export controls, which now snag quantum tech and fab equipment, and you see the squeeze on China. Bloomberg’s explainer underscores how these “chip wars” are escalating, with $81 billion in global subsidies fueling a race where China lags in cutting-edge but leads in volume. The EU, too, is fretting over China’s grip on rare-earths for defense electronics, proposing domestic recycling to break the chokehold.

For China’s supply chain, this translates to bifurcated risks: advanced AI chips scarcer due to bans, mature ones strained by demand. Q3 data shows EV chip imports down 15% year-over-year, forcing assemblers to stockpile amid fears of a 2025-2026 dip.

| Key Impact Areas | Potential Shortage Risk | China-Specific Effects |

|---|---|---|

| AI/Data Centers | High (30% demand surge by 2026) | Huawei ramp-up strains HBM supply |

| Automotive EVs | Medium-High (23% analog chip rise) | Inventory lows hit Shenzhen exports |

| Consumer Electronics | Medium | Lead times up 20%, cost hikes for PCBs |

| Industrial Controls | High (Mature node neglect) | Geopolitical leverage via capacity boom |

Navigating the Crunch: Strategies for B2B Sourcers in Electronics

So, what do you do when the chips are down—literally? First, diversify. Long-term purchase agreements with multiple suppliers, including those in India and Vietnam, can buffer against China-centric risks. Second, audit your bill of materials: standardize on industry chips to swap in alternatives if needed.

For Hong Kong-based buyers, plugged into the Greater Bay Area’s hub, this means leaning on local logistics pros for just-in-time imports while eyeing subsidies for reshoring. Recent resilience efforts—global incentives totaling billions—are bolstering chains, but execution lags. Third, monitor mature nodes closely; they’re the sleeper threat, with automotive alone facing bottlenecks that could idle 10% of production lines by mid-2026.

The Road Ahead: Resilience or Reckoning?

As Q4 2025 unfolds, the chip shortage isn’t a done deal—but the signs are flashing red. China’s electronics supply chain, resilient through past storms, now faces a multipronged assault: exploding AI needs, export iron curtains, and investment imbalances. Bloomberg’s lens reveals a nation innovating under pressure, from Huawei’s defiance to capacity gambles, but at what cost?

For global B2B players, this is a clarion call: build resilient sourcing strategies today. The multispeed recovery underway—strong in advanced nodes, shaky in mature—demands agility. Ignore it, and you might find your next order as elusive as that rumored EUV machine.

References

- Huawei to Double Output of Top AI Chip as Nvidia Wavers in China

- How Rumors of an Elusive Chip Machine Sparked a China Stock Rally

- Prepare for the Coming AI Chip Shortage

- Another Semiconductor Shortage May Be Coming

- The Global Semiconductor Crisis: A Review of Q3 2024

- Taiwan Balks on Request to Shift Its Semiconductor Production to the US

- What’s Happening in China’s Semiconductor Industry?

- Global Efforts Bolster Semiconductor Supply Chain Resilience

Disclaimer: This article is for informational purposes only and does not constitute financial, investment, or sourcing advice. Readers should conduct their own due diligence and consult professionals before making business decisions. All data and opinions are based on publicly available sources as of October 4, 2025.